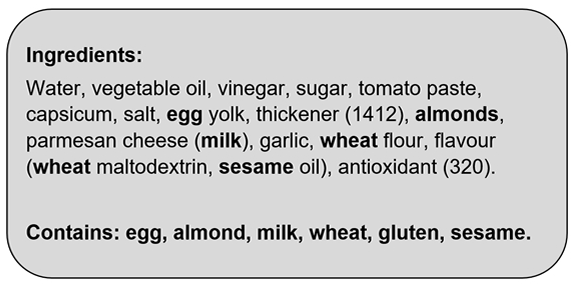

Changes in Food Allergen Labelling

Are you a food manufacturer who is required to update their labelling to highlight Allergen content of your products?

Bartender 2022 Release 4 can do this for you without and coding, VB script or text manipulations

Call Peter on 0411 713 173 for more information

Our Latest Barcode Scanner - The A-M2

Features of the A-M2 barcode scanner

Wi-Fi - 2.4G/Bluetooth/USB Type-C.

100 meters transmission distance.

350scan/s, fast scan speed.

3 hours charging time.

Size : 120mm X 40mm X 30mm

Weight : 105g

LED white light, 640*480 pixels

Operating temperature : 0 to 40 °C

Battery capacity : 1500mAh

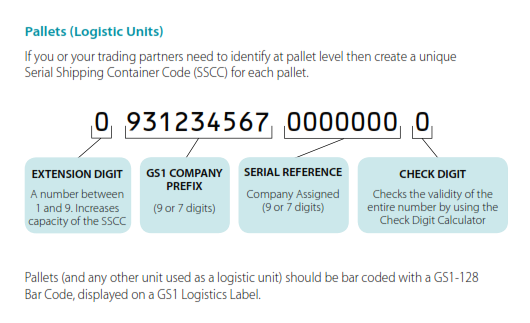

How do SSCC Barcodes work?

Most label design programs offer a Wizard which will enable you to correctly format SSCC Barcode.

Above is an example of an SSCC barcode. More information can be obtained from either the attached GS1 brochure or directly from GS1

This barcode is generally required by the larger grocery chains and is used to improve the efficiency of their warehouse management system as part of their EDI (Electronic Data Interchange) system.

The SSCC barcode contains information about both you as a supplier as well as your product, the production use by date, and in the simplest form a serial number that is unique to should to shipping unit.

It is imperative that the serial numbers are absolutely unique otherwise it is likely that your shipment will be rejected at your cost.

The first component of the SSCC barcode is your manufacturing ID which is generally 7 or 9 digits. The next component is a serial reference number (see above).

Note there is only one acceptable format from the date code which is YY MM DD.

Much of the information that is to be inserted into the barcode can also be obtained from a database. Most of the label design software programs have the ability to connect to multiple data sources, from something as simple as a text file right up to an SAP database

The serial number can be of any format but must need the minimum number of digits requirement.

The label format usually used for the logistics industry is 100mm X 150mm. It is important to respect the recommended label format and size of the barcode to ensure that your product is delivered correctly.

For more information about SSCC barcodes click on the link below

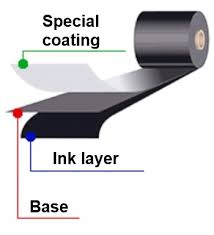

CSI (Coated Side In) or CSO (Coated Side Out) printing

Thermal transfer ribbons come in a multitude of formats. Variations include the ink layer make up which can be wax (generally for use on paper labels), wax/resin combination or full resin which is suitable for use on synthetic labels. These are generally designated as B110A for paper labels and B110C for synthetic labels

They can be wound as CSI ( Coated Side In) which means that the ink layer is wound inside the roll. This was the format for the older Datamax printers however the latest printers can use either CSI or CSO

or CSO (Coated Side Out) which means that the ink layer is wound to the outside of the roll. This format is generally used on Zebra printers.

Other variations include the ribbon width which will depend on the printhead width - note the ribbon should be at least 1.5mm wider than the printhead (on each side) to prevent wear to the printhead and premature failure, the core size - usually either 13mm or 25mm, whether the core is notched or not, whether the lead-in or lead-out requires special coating (such as clear or silver) and finally the length. the length is usually determined by the printer and can be 74m, 91m, 152m, 300m, 360m, 450m or 600m

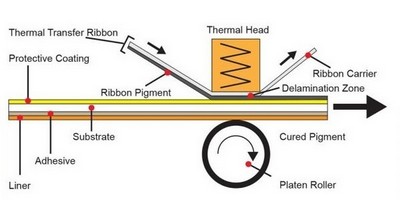

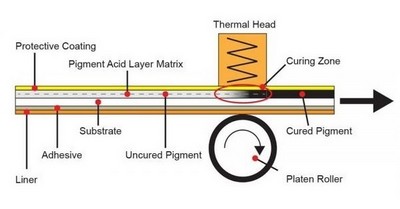

What is the difference between Thermal Transfer and Direct Thermal printing

Thermal Transfer Printing

Thermal transfer printing is a digital printing process in which material is applied to paper (or some other material) by melting a coating of ribbon so that it stays glued to the material on which the print is applied. It contrasts with direct thermal printing where no ribbon is present in the process. It was invented by SATO corporation around the late 1940s

Direct Thermal printing

Thermal printing (or direct thermal printing) is a digital printing process which produces a printed image by selectively heating coated thermochromic paper, or thermal paper as it is commonly known, when the paper passes over the thermal print head. The coating turns black in the areas where it is heated, producing an image. Two-colour direct thermal printers can print both black and an additional colour (often red) by applying heat at two different temperatures.

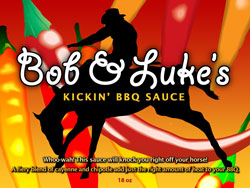

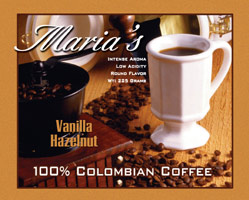

High quality colour label printing

As a small business owner have you ever wished that you could print high quality colour labels for your products and give them the same professional look as products manufactured by "Big Business".

Small businesses these days increasingly find that their labelling costs are spiralling out of control. To get a cost effective unit price it is necessary to order large quantities of labels which can impact on storage capacity, cash flow and the ability to change quickly to meet ever changing consumer demands.

On the one hand it is cheaper to produce a large quantity of labels at a time but this has drawbacks in that it does not allow for custom products, test run products or give the small business owner the ability to custom package products on behalf of a major customer if required. Also there could be the issue of wastage of labels that have been printed for products that are no longer required or available. This can seriously impact on the business bottom line.

The Primera range of colour inkjet printers gives small business the ability to compete, not only in the realm of product quality, ingredients and price but also in the visible impact area.

The LX500 is the entry level printer is the range and is suitable for a small home business with a faily low product output.

The LX500 produces gorgeous, professional-quality labels for all your short-run, specialty products. It’s ideal for industries such as gourmet foods, wine, personal care and natural products. It is also perfect for a host of other uses such as proofing before going to press on longer runs.

The next step up is the LX1000 and the LX2000 which gives the SME operator a competitive advantage when it comes to labelling quality. Both printers use Color Shield, pigment inks which have been tested under extreme conditions, including exposure to UV light and repeated salt spray and immersion. All for a fraction of the cost of buying a large number of labels, warehousing them and perhaps disposing of them should change be required. Finally with these printers you can print 1 label if required.

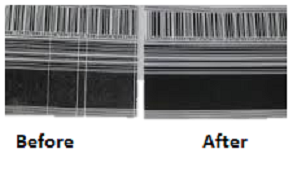

Importance of caring for your thermal printhead

The thermal printhead is the most sensitive and expensive component to replace in a thermal printer. The printhead should never be touched with the fingers and especially not with anything sharp such as a screwdriver or scissors as the head can be destroyed completely. Thermal printers, just by the fact of using paper for the printing process, are exposed to paper dust. Also if the printer is working in an environment that is exposed to the elements –such as a warehouse which is open to the outside world or is situated in a dusty or wet environment the potential for damage in multiplied.

There are many symptoms that indicate that the printhead needs a clean. The photo below shows the print before and after cleaning the printhead

To ensure the longest life for your printhead it is recommended that it be cleaned regularly. The cleaning process should be made a part of the routine and as it is a simple process involving just 1 minute so there is no reason that this function can’t be carried out say at the beginning or end of each day

The cleaning process consists of a few simple steps.

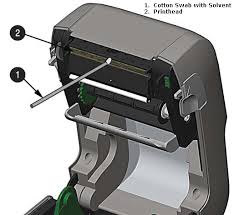

1. Open the printer to expose the printhead |  |

| 2. Using a cleaning pen gently wipe the printhead area by moving the pen from side to side as shown at left. |

Also it pays to periodically clean the paper path using an impregnated cleaning card. This will remove any paper dust which accumulates inside the printer on its working surfaces. |  |

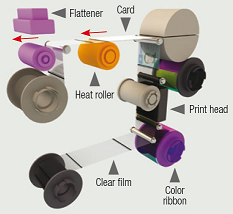

Plastic card printers - How does Retransfer Technology Work?

The card is printed in two phases. Firstly the card design is printed by Dye Sublimation onto a transparent film. The printed film is then fused to the plastic card using a high temperature bonding method producing superb cards. The Evolis Avansia ID card printer is suited for high security card printing and can produce high quality prints which extend over the edge to ensure the highest quality print. The Avansia is a dual sided card printer which has the option of many encoding upgrades including MAG, mifare and non contact cards.

Retransfer technology (reverse transfer) maximizes print quality with the Avansia being able to produce 600 dpi resolution. The Avansia card printer also has a built in flattener that applies pressure on the card to ensure a flat surface. This is important as it allows this machine to produce the highest quality cards which are also completely flat. This machine can print 140 single sided cards per hour, has a high capacity card feeder tray can hold 250 cards and the printer consumables print 500 prints per roll so you can print your cards without interruption. Robust build quality reflected in a 3 year warranty and life time warranty on the print head. The Avansia can print on all types of cards (PVC, PET, Polycarbonate, ABS etc..), including smart and contactless.

What is Dye Sublimation?